The CETATEST 825 is the fourth generation of CETA differential pressure testers.

The differential pressure leak test is based on the comparison of the pressures in the test part volume with the pressure in a tight reference volume. It can be used for fully automatic leak test processes within the cycle time of the production line.

The integrated 7-inch touch-screen with an intuitive operable graphical user interface makes it possible to display a wide range of information (for example, measurement curves, histograms). Operation is possible both via the touch-screen and via a dual-jog dial. Separate start / stop buttons ensure operating safety even in harsh industrial environments. Prepared for Industry 4.0 requirements

The memory stores more than 1 million measurement results and 256 test programs

| Specification | Details |

|---|---|

| Pressure Sensors | Gauge pressure sensor, Differential pressure sensor |

| Pressure Ranges | -1 bar, 200 mbar, 1 bar, 6 bar, 10 bar, 20 bar, 30 bar Negative and positive gauge pressure ranges can be combined (e.g., -1 bar / +10 bar) Other pressure ranges available on request |

| Measurement Ranges | ±500.0 Pa / ±5,000 Pa Internal resolution: Effectively 0.01 Pa |

| Result Units | Pa, hPa, PSI, Pa/s, hPa/s, PSI/s, mbar·l/s, ml/min, ml/h, l/min, l/h, mmHg, Torr, mmWs |

| Test Modes | Pressure decay |

| Optional Test Modes | Sealed component, Dynamic pressure, Pressure steps, Pressure rise |

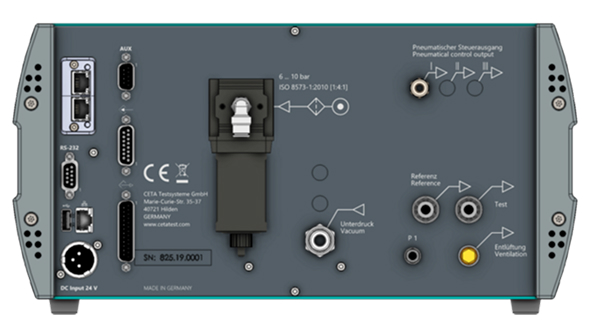

| Interfaces | I/O interface for start/stop/reset, program selection, device status, system errors, test results (pass/fail) RS-232, USB (host), Ethernet for additional functions like parameterization, measurement results, real-time data (e.g., measurement curve), failure messages Optional Interfaces: Profibus DP, Profinet, EtherCAT, USB (Slave) |

| Industry 4.0 Compatibility | The CETATEST 825 is fully interface compatible with the CETATEST 815 |

| Dimensions (W×H×D) | 367 mm × 183 mm (4U) × 435 mm |

| Typical Applications | Components that should be waterproof, oil-tight, or gas-proof |

WhatsApp us